FLAVORx Auto

A spoonful of FLAVOR helps the medicine go down!

Picture this: a child grimacing at the taste of their medicine while their parents and pediatrician share a mutual sense of frustration knowing that not taking the full spoonful means not taking the dose they need.

Since 1995, FLAVORx has been committed to addressing the challenge of bitter-tasting liquid medicine by empowering pharmacist with the ability to flavor them. And thanks to the FLAVORx Auto and Fillmaster UV, those busy pharmacists can now give their customers their choice of flavors in the same time it used to take them just to reconstitute those liquid medications from powder form.

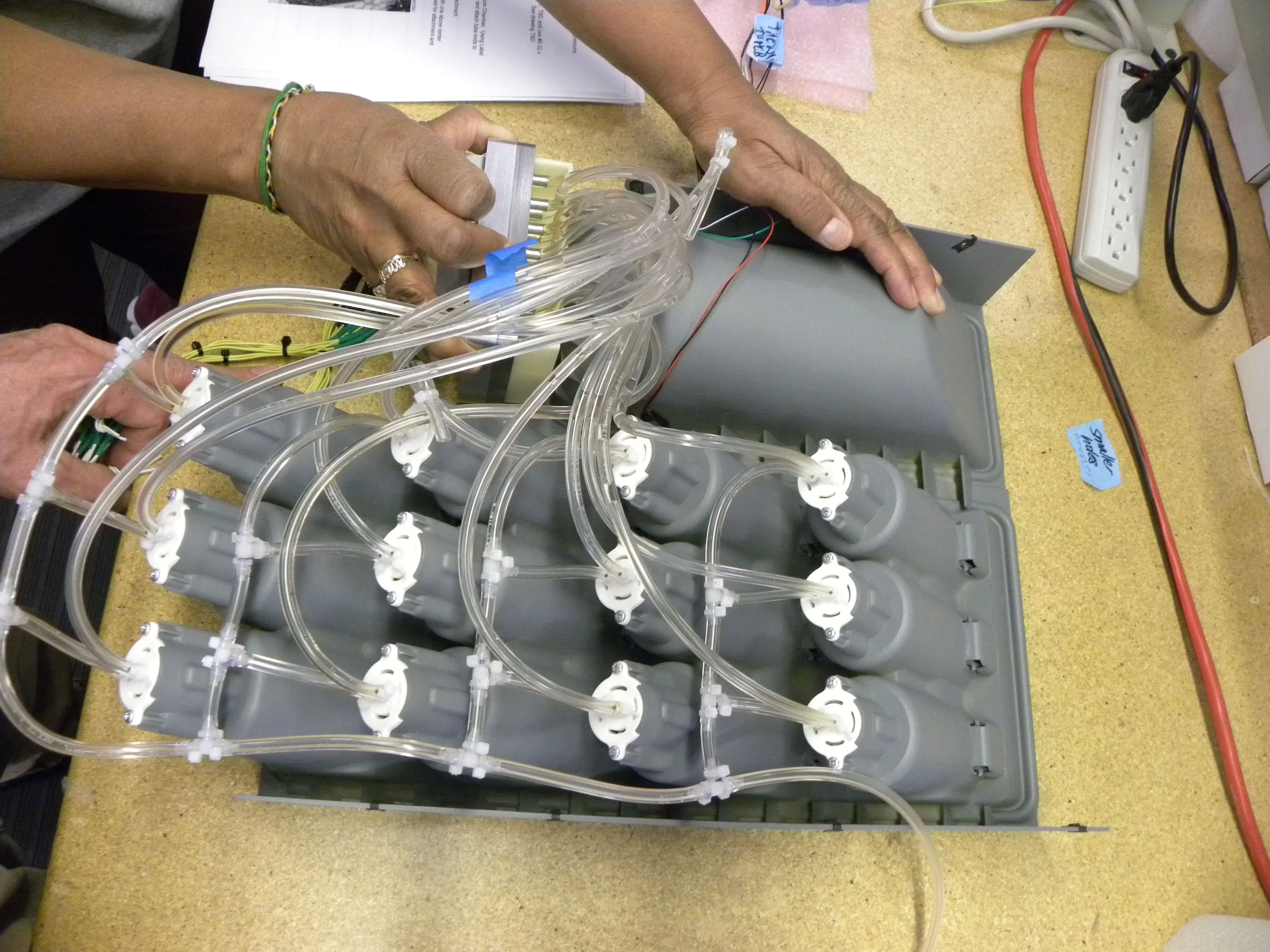

With 12 unique flavorings to choose and automatically mix from, these machines are a game changer for pharmacists who want to ensure their customers satisfaction and compliance, as well as make good use of their very limited time.

Harbor Designs and Manufacturing’s Role: Research, testing, proof of concept, test fixture development, prototyping, design for manufacturing, cost optimization, turnkey supply chain management, technical assembly, quality assurance

The Remedy To Bitter Tasting Medicine

FLAVORx was founded on the mission to improve patient outcomes by removing the significant barrier posed by bitter tasting medications which are unpalatable and off putting, especially to children. If each teaspoon of amoxicillin is a a nose pinching negotiations between a child and their parent or doctor, patients run the risk of not taking their proper dosage and unnecessarily dreading medication time.

The FLAVORx team conducted meticulous studies to determine which flavor combinations worked best with different liquid medications and quickly gained market penetration into nearly all US pharmacies as a palatable option for pharmacists to offer their customers. What’s more, it gave pharmacies the ability to charge for flavoring which gave them the potential for a significant revenue boost to existing sales, with nearly zero cost of customer acquisition. In fact, it became a solution they could market to set themselves apart. But while sales were good and pharmacies and patients were happy, a significant portion of the prescriptions that could be flavored, weren’t being captured.

The problem? Overworked pharmacy staff with no time to spare weren’t interested in creating even more work for themselves, so they often didn’t mention it as an option when customers came to fill their prescriptions. FLAVORx had done a great job of characterizing each liquid medication, formulating recipes and recommendations, and even created a flip book that showed pharmacist exactly how many mL of cherry, or sweetening enhancers to add, but going to the flip book and manually mixing three or more different volumes of flavors, as they worked to reconstitute the medications from powder, was asking a lot of them.

The solution was to develop an automatic dispenser programmed with all of those recipes, and capable of reconstituting, metering, and flavoring any medication faster than pharmacist could just reconstitute those medications in the past. What was once a time-consuming, error-prone process for pharmacists could now be done safely and quickly.

Overview of the FLAVORx Auto. Image from Fillmaster Systems.

A User-Centric Design

The pharmacist taps the screen and holds a powder medication bottle up to the barcode scanner which determines the medication and bottle size which displays on the screen, along with favor recommendations that pare well with the medication. The pharmacist has the option to just reconstitute the medication or select the patients preferred flavor. With the touch of a button they can reconstitute and add flavor recipes in just 15 seconds. A considerable improvement over reconstituting manually which is typically done by measuring water in a graduated cylinder. The systems are installed with 6 stages of water filtration including reverse osmosis and UV purification, ensuring what comes out of the machine is exactly as it should be. The system even self cleans after each flavor dispense to prevent accidental contamination or inadvertent flavor mixing.

Scan barcode interface of the FLAVORx Auto.

Based on consumer testing feedback,7 the system presents the best or most popular flavor options for the medication, other acceptable options, and grays out options that are not recommended, or empty.

Pharmacist Ursula Chizhik using the touchscreen interface of FLAVORx. Image courtesy of Baltimore Sun.

FLAVORx Auto introduces automation and saves pharmacists time, greatly enhancing patients' medication experience. The variety of flavors ensures that even the smallest patients view medicine time as enjoyable rather than something to avoid—making for healthier kids and happier families.

The systems have been adopted by all of the large pharmacies like Rite Aid, Walgreens, CVS, Target Pharmacy, Harris Teeter Pharmacy, and many others so look behind the counter the next time you find yourself picking up a medication, and if it happens to be liquid, ask them what flavors the FLAVORx Auto recommends!

“Gone are the days of looking up a recipe and measuring out flavor with a syringe. The Auto seamlessly integrates flavoring into the reconstitution process, so adding a favorite flavor is as easy as scanning the medication’s bar code.”

The Smile-making Machine

FLAVORx has been embraced by over 45,000 retail pharmacies, hospitals, and veterinary clinics across North America. Its products have been used to custom flavor over 150 million prescription medications. It also received H-E-B pharmacy’s 2018 Service Supplier of the Year award.

“The FLAVORx Auto represents a groundbreaking approach to time-saving and efficiency within the pharmacy,” remarked Stuart R. Amos, President and CEO of FlavorMaster, LLC.

Pharmacist Ursula Chizhik uses the FLAVORx Auto. Image courtesy of Baltimore Sun.

In the competitive world of healthcare, setting yourself apart is key. FLAVORx Auto has enabled pharmacies to transform their approach, putting patient care at the forefront.

This innovative, essential solution has not only attracted new customers but also created better health outcomes in children.